Zero Oil Revolution, Eternal

Power - The New Benchmark for Railway Special Used Piston Compressor

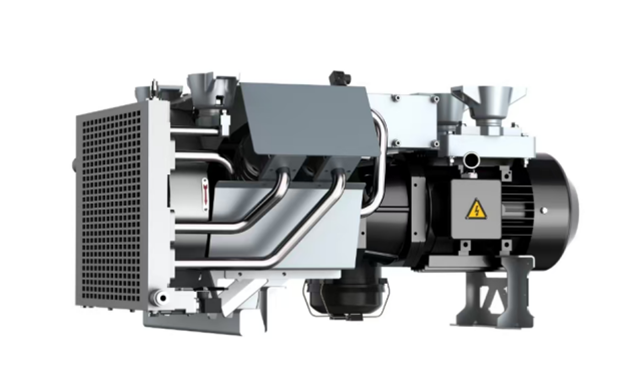

Recently, an oil-free piston compressor designed specifically for the Russian railway environment has been officially put into use, becoming a new technological benchmark in the field of railway power equipment in the country.This machine has the core advantage of "silent and oil-free, eternal power", Through zero oil lubrication technology, efficient operation is achieved while significantly reducing noise pollution, perfectly adapting to the extremely cold climate and high load transportation scenarios in Siberia.

The technical director of the Russian Railway Group stated that traditional piston machines are prone to oil solidification problems in severe cold, while the new oil-free piston machines maintains stable output in -40 ℃ environment through precision sealing and material innovation, significantly improving equipment life and operation efficiency. In addition, the low noise characteristics are particularly suitable for urban hubs and tunnel operations, reducing interference with the surrounding ecology.

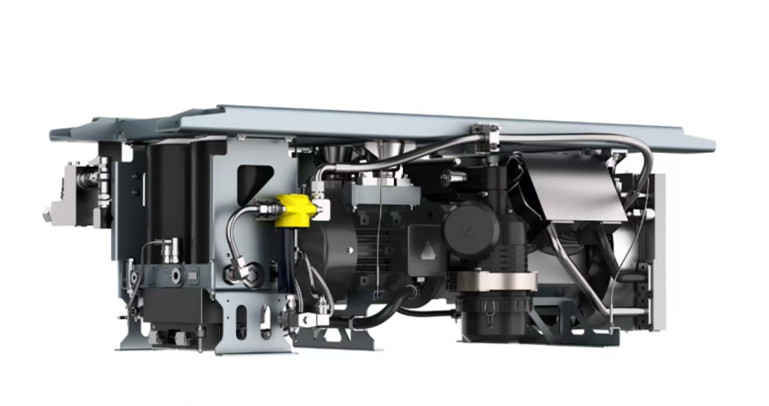

As a key achievement under the framework of "China Russia Railway Cooperation", this equipment is ready for testing and use in the Moscow to Kazan section, and will gradually be promoted to national trunk lines in the future, helping Russian railways transform towards low carbonization and intelligence.

Core Technological Breakthrough:

. Self Lubricating Ceramic Coating Technology:The surface of the piston ring is coated with nanoscale silicon carbide ceramic, with a friction coefficient as low as 0.05, which is 70% lower than traditional cast iron materials, meanwhile possessing anti-wear and corrosion-resistant properties, maintaining stable performance even at extreme temperatures.

. Precision Sealing System:Adopting a multi-stage labyrinth sealing structure, combined with high-temperature fluororubber material, ensures air leakage rate of less than 0.1%, significantly improving compression efficiency and reducing energy loss.

Intelligent Temperature Control Module:Built in temperature sensor and adaptive adjustment system, real-time monitoring of piston temperature, and through dynamically adjusting the operating frequency to avoid local overheating, the equipment can operate efficiently within wide temperature range of -40 ℃ to 120 ℃.

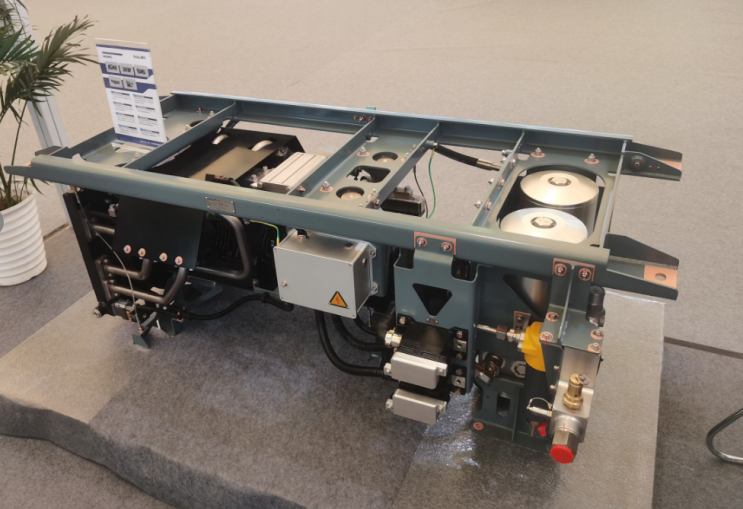

· Power Range:2.2~9.5kW

· Free Air Delivery:200L/min~950L/min

· Working Pressure:10bar

· Noise :≤76dB(A)

· Structure:Two level compression

· Cooling method:Air