NAILI Md Series For a Modular Option For The Rotary Vane Compressed Air!

The purpose to make MD series as NAILI’s aspect, important to think about the compressor still in operation during maintenance, maybe two days, one week or even more? But you need the compressed air for the production, aren’t you? MD series can make it happened!

-Modular design;

Maximum 6 sets in one cabinet to get 350hp;

-Fixed or variable speed;

High-performance inverter option;

-Easier for maintenance;

One run one standing by!

Operating principle ---

Vane compressor as below:

Maximum efficiency of the air compression process, excellent reliability, and low running costs; are just some of the key benefits that rotary vane technology can offer.

The vane compressor is a volumetric rotary compressor that consists of a stator cylinder in which a rotor is mounted off-center but parallel to its sides. The rotor has slots in which the vanes are free to slide: centrifugal force keeps them in contact with the sides of the stator during rotation.

The rotary vane compressor, thanks to its simple construction, offers remarkable advantages, first among them being greater volume yield because the vanes are in constant contact with the inner wall of the stator and form a perfectly airtight seal with no leaks along the wall thanks to a continuous film of oil. In this type of compressor, no axial thrust is generated so the side surfaces of the rotor are not subject to wear and thus no rotating bearings or thrust bearings are needed. The vanes, too, because of the special way they are made have practically Unlimited life.

Behind the success of NAILI compressors, there is thus extreme reliability, long life, quiet operation, and simplicity of maintenance. Design is important too: compactness and clean lines, together with harmonious shapes, give NAILI compressors an image of robustness and ease of use.

The rotary vane compressor, thanks to its simple construction, offers remarkable advantages, first among them being greater volume yield because the vanes are in constant contact with the inner wall of the stator and form a perfectly airtight seal with no leaks along the wall thanks to a continuous film of oil. In this type of compressor, no axial thrust is generated so the side surfaces of the rotor are not subject to wear and thus no rotating bearings or thrust bearings are needed. The vanes, too, because of the special way they are made have practically Unlimited life.

Behind the success of NAILI compressors, there is thus extreme reliability, long life, quiet operation, and simplicity of maintenance. Design is important too: compactness and clean lines, together with harmonious shapes, give NAILI compressors an image of robustness and ease of use.

MD Series Cutting-edges ---

A lower wave of Starting Current: When the air compressor starts up with a single unit sequence, the starting current fluctuation is significantly reduced so as to avoid the severe impact of the starting current of a high-power machine on the production (electricity) network system, and is conducive to the maintenance of the production system.

BACKUP security: Double Airends design, BACKUP to make sure one of them can be operating during of other down in daily production, more security and more economical way to keep production running!

More flexible setup of loading: For production needs, the compressor’s airflow and working statue can be adjusted according to actual need;

Linkage control: When airflow demand of compressor decreases, it can be operated under low load, with one full load and one unloading; In the case of even lower air consumption, one on and one standby can be provided, which not only greatly saves energy efficiency, but also provides additional guarantee for production.

MD Series Specification ---

Model | Unit | MD75 | MD90 | MD110 | |

Intake Pressure | Bar | 1.0 | 1.0 | 1.0 | |

Ambient temperature | ℃ | 0-45 | 0-45 | 0-45 | |

Relative humidity | % | 0-90 | 0-90 | 0-90 | |

Free Air delivery | 8bar | m3/min | 13.60 | 16.56 | 20.00 |

10bar | m3/min | 11.32 | 14.00 | 17.80 | |

13bar | m3/min | 9.60 | 11.76 | 14.40 | |

Air discharge Temp (higher than ambient temp) | ℃ | 5-10 | 5-10 | 5-10 | |

Oil carryover | PPM | 1.5 | 1.5 | 1.5 | |

| Drive method | Direct | Direct | Direct | ||

Rotational speed | (r.p.m) | 1475 | 1475 | 1480 | |

Oil System capacity | L | 19*2 | 19*2 | 19*2 | |

Air outlet size | DN65 | DN65 | DN65 | ||

Dimensions | Length | mm | 1800 | 1800 | 1800 |

Width | mm | 1560 | 1560 | 1560 | |

Height | mm | 1700 | 1700 | 1700 | |

Weight | kg | 1500 | 1700 | 1900 | |

Electric starting | Star-Delta | Star-Delta | Star-Delta | ||

Electric motor power | KW | 37*2 | 45*2 | 55*2 | |

Insulation class | F | F | F | ||

Enclosure class | IP55 | IP55 | IP55 | ||

Service factor | 1.2 | 1.2 | 1.2 | ||

Power supply | V/Ph/Hz | 380/3/50 | 380/3/50 | 380/3/50 | |

Supply wire min section | mm2 | 120 | 120 | 120 | |

The motor of voltages will be available according to your request, so please confirm with us in advance!

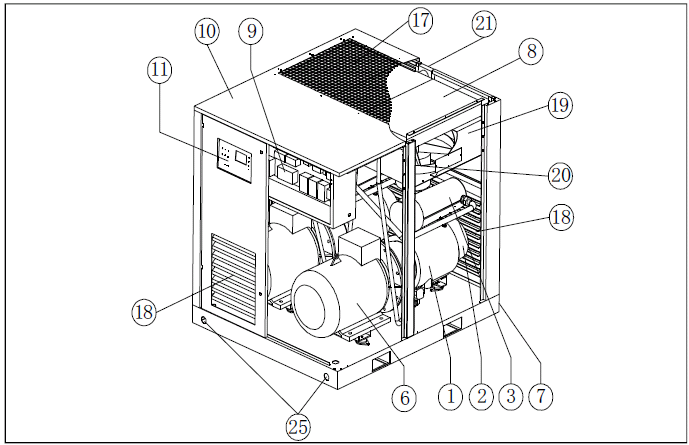

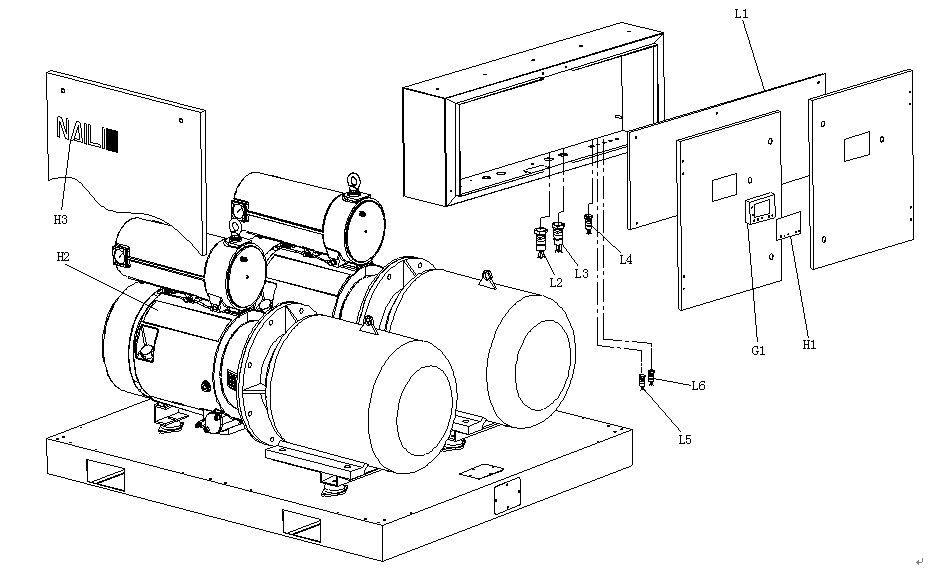

MD Series configuration ---

PartS list of MD series